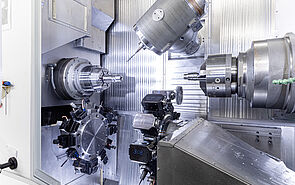

Tools and Equipment are Required in Assembly, Stamping Technologies and in Piece Parts Production as well as in Quality Assurance and in the Laboratory

These are often highly specialized and precise designs, forming the basis of an efficient value-added chain. At the Rosenberger Group the development and manufacture of high-tech components, tools and complex operating equipment is therefore carried out by its own personnel. As designers and toolmakers, these successfully contribute the competence and experience necessary in manufacturing, assembly and stamping technology as well as fixture construction. Every tool produced and all material selected serve precisely defined applications which in turn demand dedicated approaches to design and implementation.