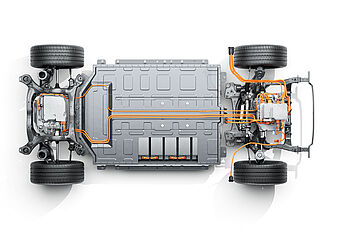

The transition from combustion engines to electric vehicles is making road transportation more climate-friendly and sustainable. This shift demands continuous innovations in connector technology. Electrical components must not only be robust, space-saving and lightweight as possible, but also capable of safe operation at high voltages and extreme currents. Our primary goal is to deliver the lowest possible contact resistances with optimized EMI performance characteristics while maintaining reliable quality standards. Our HV range includes highly compact connection solutions operating at up to 1000 V with continuous currents ranging up to 450 A.

Rosenberger works closely with automotive manufacturers, TIER1 suppliers, and harness makers to develop tailored or custom solutions and facilitate the integration of their products into various vehicle models. This collaboration helps in understanding the manufacturers' requirements and delivering solutions that meet those needs.